cn

cn

On September 22, "Oil and Gas Energy Conference of the Western Expo", with the theme of international oil and gas cooperation and energy transformation with the Belt and Road Initiative, invited many subsidiaries of Sinopec to participate, so as to help participating enterprises to understand Sinopec's development status and procurement process, and strengthen exchanges and cooperation with Sinopec subsidiaries. Chairman of KLT CARBIDE CO.,LTD, Zou Zheng (the second from left in the front line) was invited to attend the conference.

Chairman of KLT CARBIDE CO.,LTD, Zou Zheng made a keynote speech on "Application and Development Trend of Material Surface Treatment Technology in Oil and Gas Equipment Industry" in the "Exploration Technology Exchange" segment of the conference.

Founded in 1988, after 30 years of development, the company has become a medium-sized enterprise with two domestic subsidiaries (Guanghan Branch, Chengdu Branch) and one foreign subsidiary (American Branch).

In 2014, the company passed ISO 9001:2008 International Quality System Certification, ISO 14001-2004 Environmental Management System Certification and OHSAS 18001:2007 Occupational Health Management System Certification. The company has many core technologies such as nickel-based carbide, titanium-carbide-based carbide, compact flexible processing, high efficiency forming of carbide spheres and so on. The company has successfully applied for 21 invention patents and 4 utility model patents, of which 9 invention patents and 4 utility model patents have been granted authorization certificates.

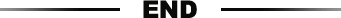

For the product and market sectors, the market situation of "sealing ring and shaft sleeve" and "nozzle and valve" are listed respectively.

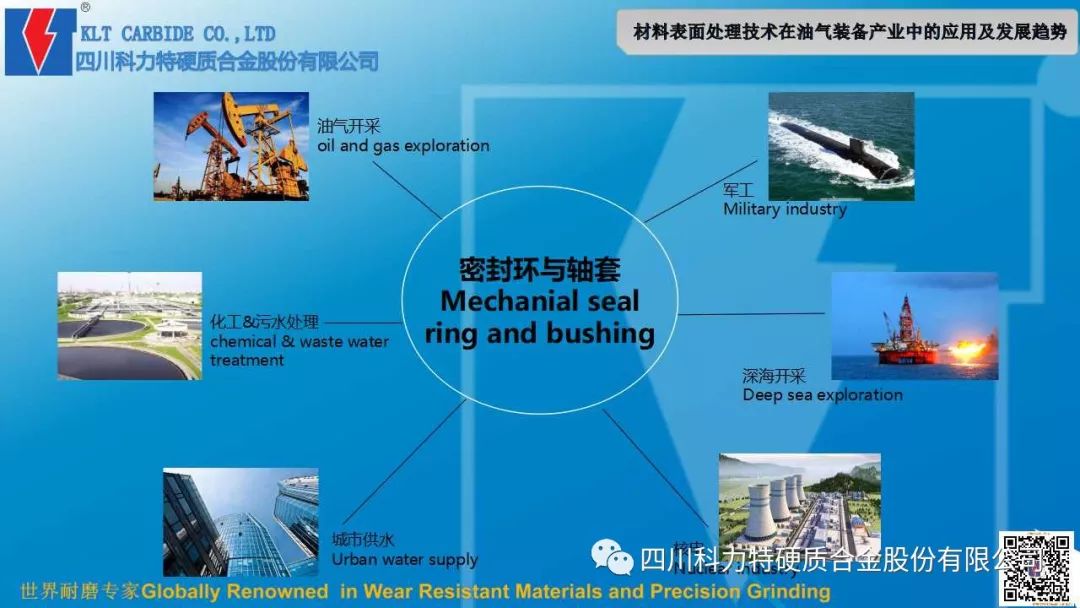

The application of material surface treatment technology in oil and gas equipment can be divided into design, manufacture, maintenance, repairing/remanufacturing, which mainly reflects its anti-corrosion and wear-resistant effect.

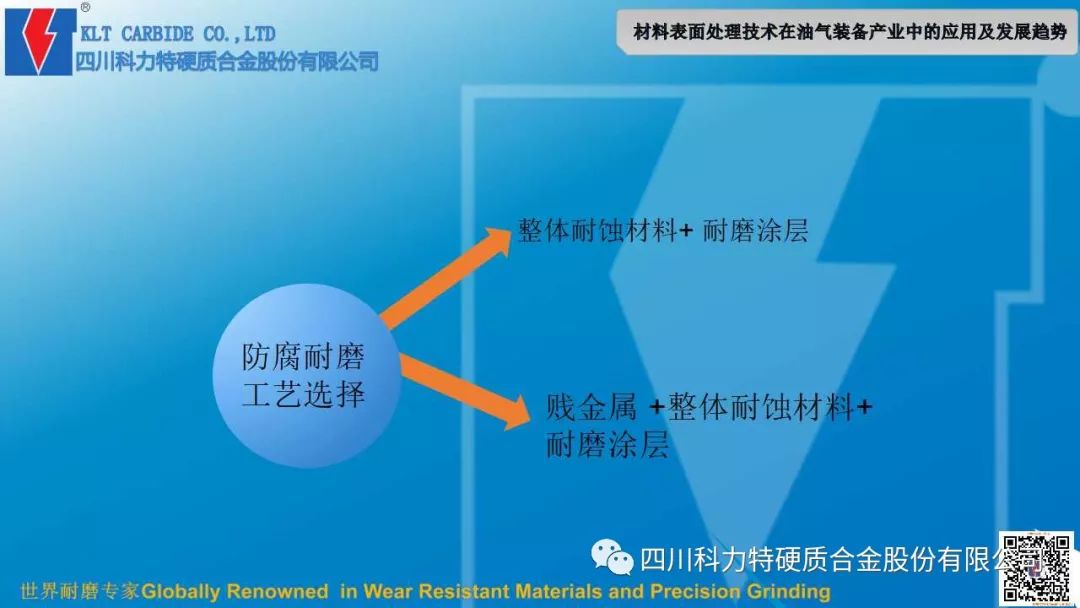

01 Application in Well Completion

Repair and reinforcement of downhole working tools including wear parts of plungers, cylinder liners and impellers of various types of pumps - such as HVOF spraying WC-Co or plasma spraying Al2O3, etc., or arc spraying 1Cr13 repair. The life of WC piston rod sprayed by HVOF can be increased several times.

Sources of corrosion: galvanic corrosion, CO2, H2S, high temperature (90-120 ℃, 194-248 ℉)

HVAF spraying super stainless steel replaces arc spraying Monel alloy+resin sealing technology. The technology has been successfully used in Russian oil fields, and has help spray pump shells of more than 48000 meters. At present, hundreds of new pump shells and pumps and motors are sprayed every month.

02 Application in Oil Transportation

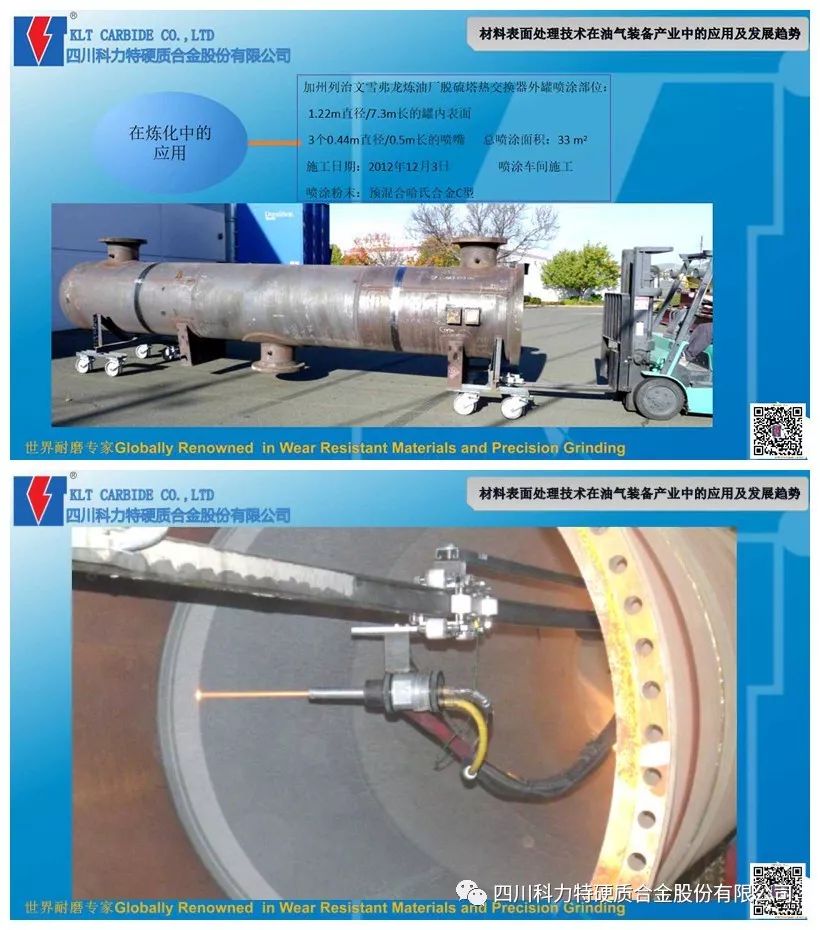

03 Application in Refining and Chemical Industry

Spraying position of external tank of heat exchanger of desulfurization tower in Richmond Chevron Refinery, California:

The inner surface of 1.22m diameter/7.3m long tank

Three nozzles with 0.44m diameter/0.5m length

Total spray area: 33 square meters

Date of construction: December 3, 2012

Construction in Spraying Workshop

Spray Powder: Pre-mixed Hastelloy C type

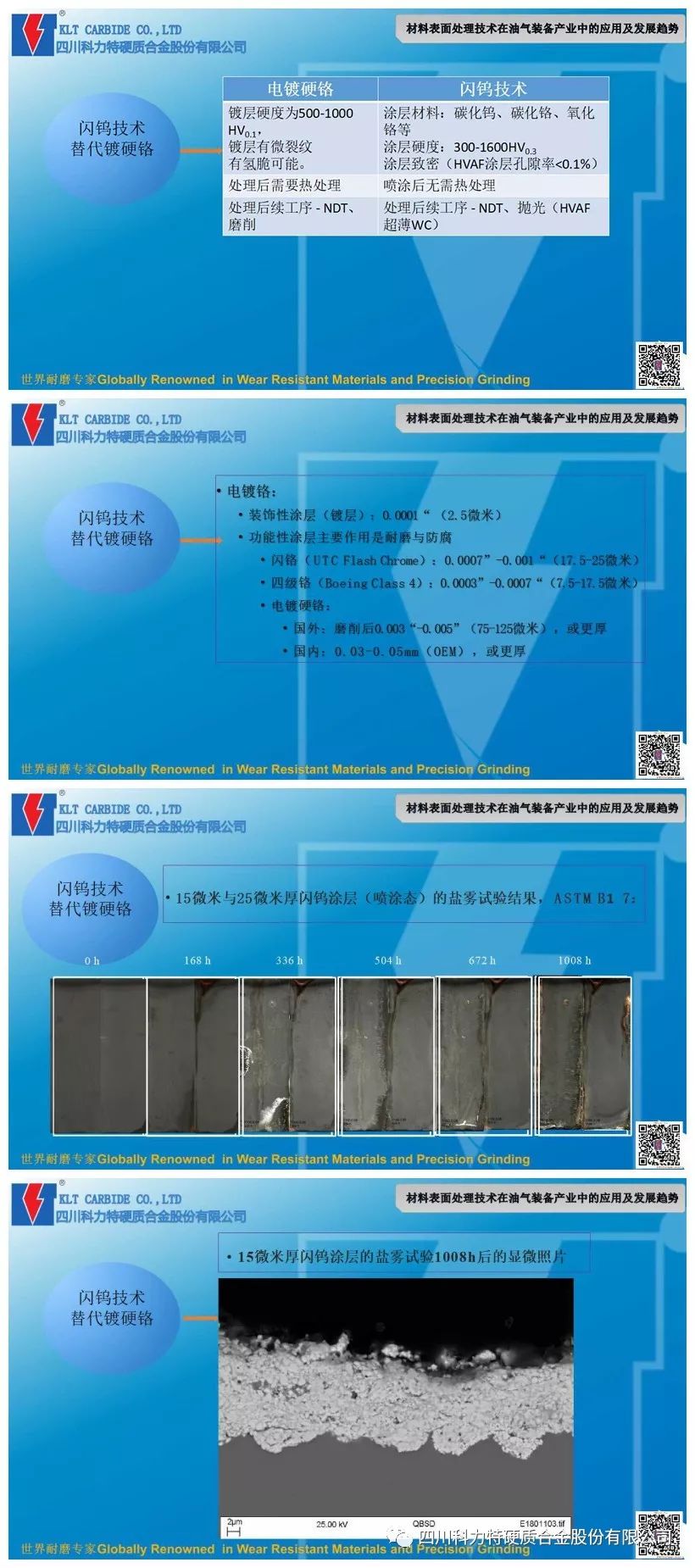

Regarding the development trend of material surface treatment technology, Chairman Zou said that the flash tungsten technology in the surface treatment of materials will replace hard chromium plating in the near future.

In addition, remanufacturing technology is also the future trend of surface treatment technology. With the support of surface engineering theory and remanufacturing theory, the waste tubing is remanufactured by the principle of self-propagating high-temperature synthesis. A ceramic layer oxide of alumina is compounded inside the pretreated waste oil pipe. By the action of centrifugal force, the liquid metal generated in the reaction process is filled in the corrosion area or wearing area of the waste oil pipe to restore the geometric size of the oil pipe, and it is remanufactured as a cermet composite tubing through a standard API production line.

Finally, Chairman Zou concluded that: "Environmental friendliness and resource efficiency are the basic requirements for future development. Material surface treatment technology can enable our equipment to achieve long life, maintenance-free and efficient operation."